From Crewe to Montreal: How a Bentley Is Built - 130 Hours of Handcraftsmanship Explained

Every Bentley that arrives in Montreal begins its journey in Crewe, England, where skilled artisans invest between 110 and 130 hours handcrafting...

Read more

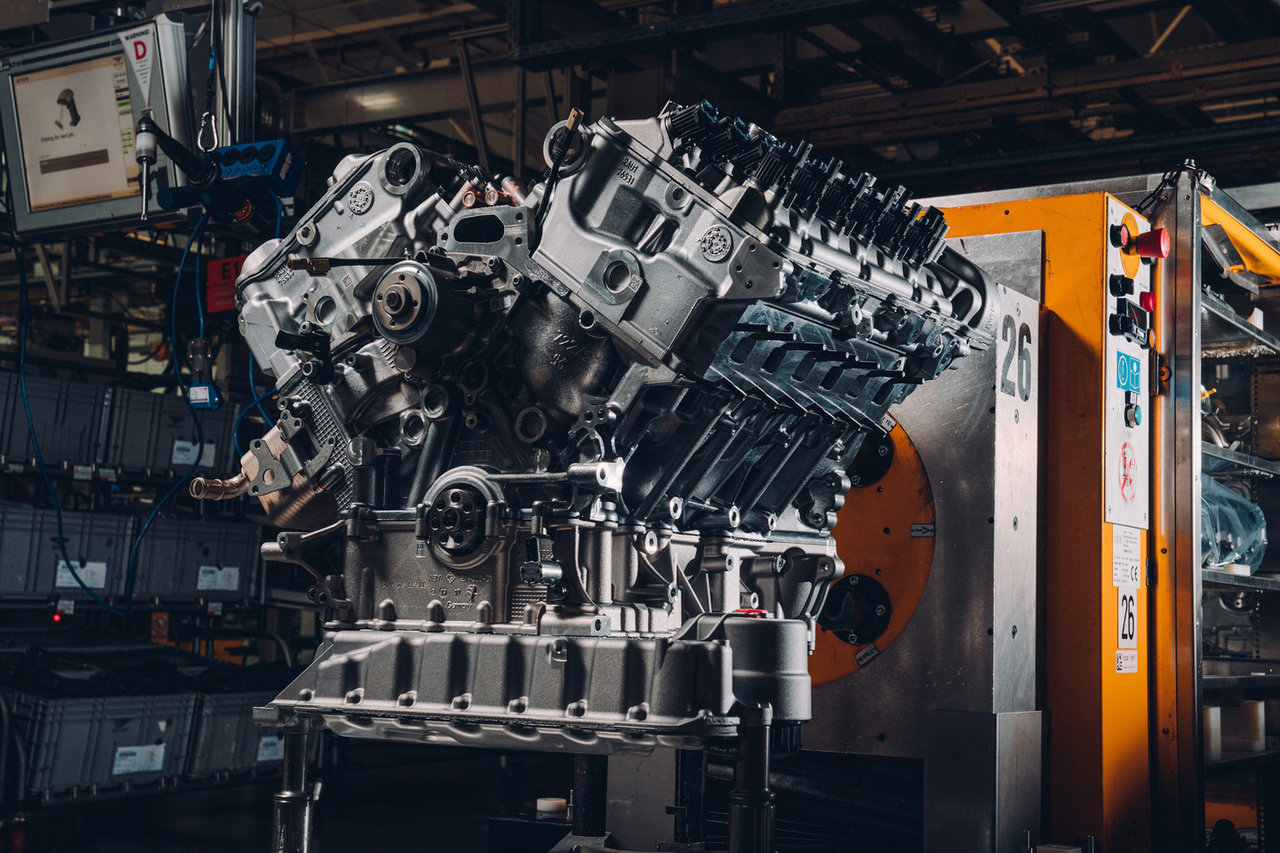

Bentley Motors has officially ended production of its legendary W12 engine at its Crewe headquarters, marking the conclusion of a significant era for the luxury automaker. The final hand-built W12 engines will power the last Bentayga, Continental GT, and Flying Spur models equipped with this powerplant.

End of an Era

Since its introduction in the original Continental GT in 2003, over 100,000 W12 engines have been meticulously crafted at Bentley's Dream Factory. This decision aligns with the company's Beyond100 strategy, which aims to position Bentley as a leader in sustainable luxury mobility.

To commemorate this milestone, Bentley organized a special event for the W12 assembly and R&D teams. The celebration included a commemorative lunch, a group photograph, and the presentation of W12 engine pistons to assembly colleagues as mementos.

Engineering Marvel

The 6.0-litre twin-turbo W12 engine, renowned for its compact design and impressive performance, has been a cornerstone of Bentley's success for two decades. In its initial form, the engine produced 552 bhp and 479 lb.ft of torque, propelling the Continental GT from 0-100 km/h in just 3.6 seconds.

The second generation W12, introduced with the Bentayga in 2015, featured significant improvements including twin-scroll turbochargers, dual fuel systems, and cylinder deactivation technology for enhanced efficiency.

Record-Breaking Performances

Throughout its lifespan, the W12 engine powered several record-breaking vehicles. Notable achievements include Juha Kankkunen's World Ice Speed Records in 2007 and 2011, and Rhys Millen's Production SUV record at Pikes Peak in 2018.

Limited Edition Farewell

To honour the W12's legacy, Bentley has produced 120 'Speed Edition 12' models across its range. These exclusive vehicles feature unique badging, treadplates, and a numbered engine plaque, among other special touches.

The Future: Ultra High Performance Hybrid

As Bentley transitions towards electrification, the W12 will be succeeded by a new Ultra High Performance Hybrid powertrain. This innovative system combines a V8 engine with advanced battery technology, promising even greater power output while significantly reducing emissions.

Dr. Matthias Rabe, Bentley's Board Member for R&D, stated, "The W12 has propelled our cars and business forward at an exceptional speed and will go down as one of the most important innovations in our illustrious history."

With this transition, Bentley looks to the future while honouring the legacy of an engine that has played a crucial role in shaping the company's identity and success over the past two decades.

From Crewe to Montreal: How a Bentley Is Built - 130 Hours of Handcraftsmanship Explained

Every Bentley that arrives in Montreal begins its journey in Crewe, England, where skilled artisans invest between 110 and 130 hours handcrafting...

Read more

Four World-First Features Debut on the Batur Convertible

Bentley's Mulliner division has completed the Batur Convertible #4, introducing four custom features never before seen in automotive design....

Read more

Introducing the All-New Continental GT S: Hybrid Power with Driver Focus

The Bentley Continental GT S marks a bold evolution in grand touring excellence. Launched in January 2026, this fourth-generation model pairs...

Read more